CNC Machining vs. Casting: The Definitive Guide

What Defines CNC Machining Services in Modern Manufacturing

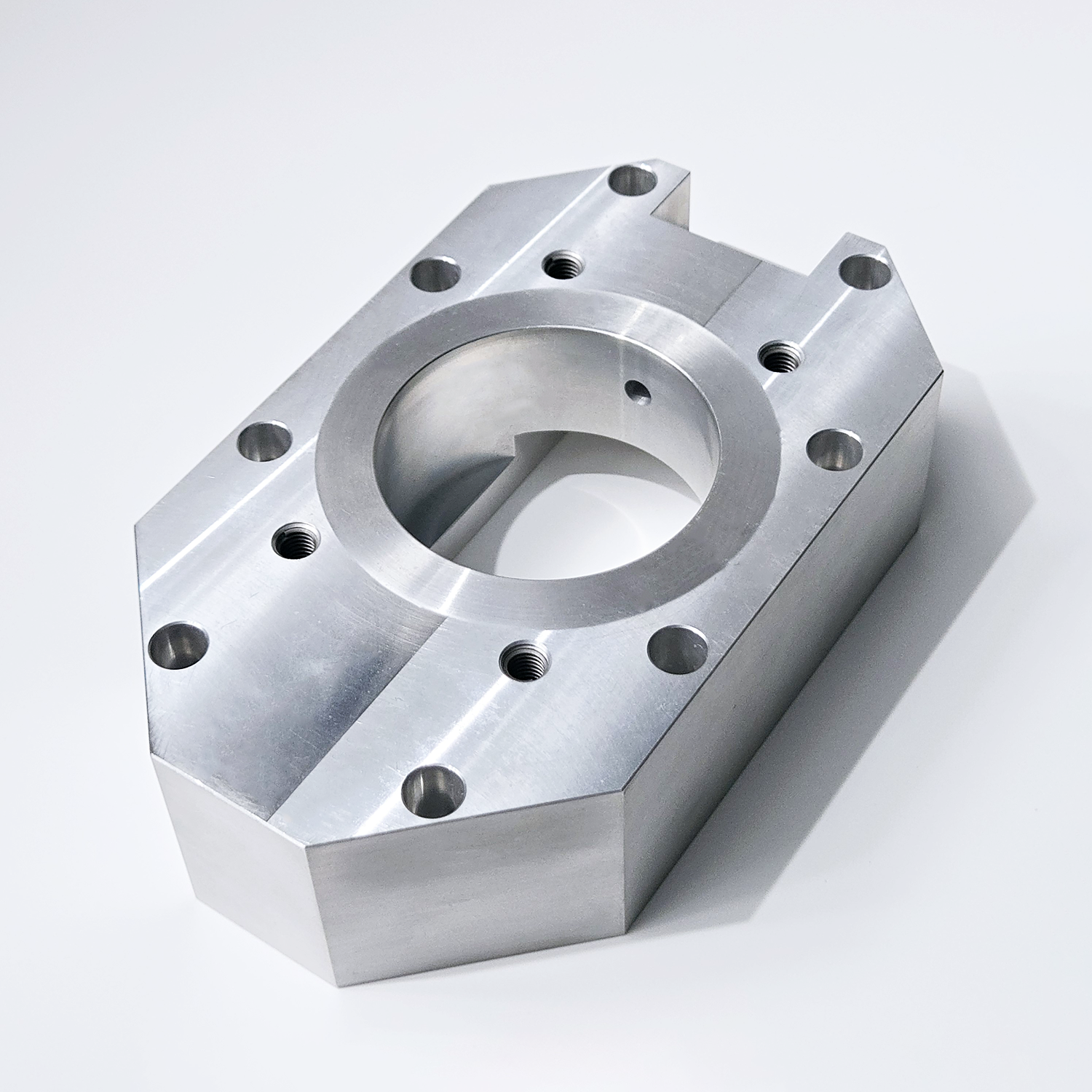

CNC machining services use computer controlled tools that cut away material from solid blocks to create exact shapes through what's called subtractive manufacturing. The main parts include things like multi axis spindles, automatic tool changers, and smart controllers which allow for really tight tolerances around plus or minus 0.005 mm. That kind of accuracy matters a lot for industries where precision is everything. According to a report on precision manufacturing released last year, these CNC systems actually cut down on human mistakes by about 73% when compared with old school manual methods, especially noticeable when making those complicated aerospace components. Top shops focus heavily on strong work holding systems and cutting tools that adjust themselves to deal with all sorts of materials ranging from regular aluminum alloys right up to tough stuff like titanium.

Core Principles of Casting: From Sand to Die Casting Methods

The casting process involves pouring molten metal into molds to create parts. Sand casting typically uses expendable molds and works well for smaller production runs, especially when making parts for heavy machinery in batches above 50 units. Die casting on the other hand relies on durable steel dies that can be reused many times, making it ideal for large scale manufacturing where speed matters most. Automotive manufacturers often turn to die casting because these machines can produce anywhere from 200 to 500 parts every hour. When it comes to quality control, factors such as the temperature at which metal is poured (usually between around 650 degrees Celsius up to nearly 1600 degrees) play a big role in determining how solid the finished product will be once cooled. Solidification rates are another important consideration throughout the process. Interestingly enough, newer developments in vacuum assisted casting techniques have managed to cut down on those pesky porosity issues by about forty percent, which means better looking surfaces across all manufactured items.

Key Differences Between Casting and CNC Machining in Material Removal vs. Formation

| Factor | CNC Machining | Casting |

|---|---|---|

| Material Action | Subtractive (removes material) | Formative (shapes material) |

| Tolerance | ±0.005±0.025 mm | ±0.1±0.5 mm |

| Lead Time | 1±5 days (no tooling required) | 2±8 weeks (mold creation) |

A 2023 Aerospace Component Integrity Study confirmed CNC machining achieved 99.8% compliance in wing spar tolerances, while casting methods struggled with less than 85% accuracy due to thermal shrinkage.

Precision, Tolerance, and Quality: CNC Machining vs. Casting Comparison

Tolerance Levels Achievable in CNC Machining vs. Die Casting Comparison

When it comes to tight tolerances, CNC machining really stands out compared to traditional die casting techniques. Most CNC operations hit around ±0.01 mm accuracy, whereas die casting usually lands somewhere around ±0.25 mm. That makes a world of difference when working on parts where precision matters most. The reason behind this gap lies in how each process works fundamentally different. CNC machines cut away material bit by bit, so there's no risk of those pesky pores that often show up in castings. Take modern 5-axis CNC systems for instance they can hold tolerances as small as 0.0004 inches even on complicated shapes. Sand casting just doesn't match that kind of consistency without going through extra machining steps afterward to get anywhere close.

Repeatability and Precision Under High-Volume Production Conditions

Automated CNC workflows deliver 99.8% repeatability across production batches exceeding 10,000 units—a feat unattainable in traditional casting operations. Casting processes face inherent variability from mold degradation and molten metal flow dynamics, often requiring 12–18% scrap allowances versus CNC machining's 3–5% waste rates in optimized setups.

Case Study: Aerospace Component Requiring Tight Tolerances Met Only by CNC Machining

A recent turbine blade project demonstrated CNC's superiority when cast prototypes failed 78% of pressure tests. CNC-machined Inconel 718 components met 0.005 mm profile tolerances critical for supersonic airflow control, achieving 100% compliance with AS9100D aerospace standards.

Advancements in Near-Net-Shape Casting Improving Dimensional Accuracy

While vacuum-assisted casting now achieves 90% dimensional accuracy in initial casts, post-casting CNC machining remains essential for mating surfaces and threaded features. New binder jetting techniques have reduced casting draft angles to 0.5°, narrowing—but not eliminating—the precision gap with CNC processes.

Material Compatibility and Design Flexibility in CNC and Casting Applications

Common Metals Used in Casting and Their Machinability Post-Production

In casting operations, materials such as aluminum A356, zinc ZA-8, and various iron alloys including gray iron (which meets ASTM A48 standards) are frequently used because they flow well and manage shrinkage effectively during solidification. Most of these materials need additional CNC machining after casting to get those tight dimensional specs right. Take die cast aluminum for instance it tends to cause tools to wear down about 20 percent quicker compared to regular wrought alloys when being milled. This finding comes from industry data published in last year's Manufacturing Materials Report by the American Foundry Society. The difference matters quite a bit for shops looking to optimize their production costs over time.

| Metal | Casting Suitability | Post-Casting Machinability Rating (1–10) |

|---|---|---|

| Aluminum A356 | Excellent | 8.5 |

| Zinc ZA-8 | Good | 9.2 |

| Gray Iron | Excellent | 6.0 |

The Makerverse machining guide highlights how silicon content in cast aluminum accelerates tool wear, requiring adaptive feeds during CNC finishing.

Material Selection in Casting and CNC Machining: Aluminum, Steel, and Specialty Alloys

While both processes handle aluminum, cast versions like 319.0 exhibit lower tensile strength (276 MPa) versus CNC-machined 6061-T6 (310 MPa). Steel components face divergent paths: investment casting suits complex shapes in 4140 alloy, whereas CNC machining services dominate 17-4PH stainless steel parts requiring ±0.025 mm tolerances.

Limitations in Material Compatibility for Internal Geometries in Casting

Casting’s reliance on mold separation planes restricts internal channel complexity. Although sand casting cores can create basic cavities, features like helical coolant paths in engine blocks require post-casting CNC drilling—adding 15–30% to production costs.

Complex Geometries: Internal vs. External Features in Casting and CNC Machining

Casting excels at producing organic external shapes like turbine housings in one piece, while CNC machining enables precise internal features such as fuel injector micro-channels (Ø0.5±0.01 mm). Multi-axis CNC systems overcome traditional limitations, machining 83° undercuts unreachable by standard casting tooling.

Design Limitations in CNC Machining and Casting for Undercuts and Thin Walls

When dealing with undercuts in castings, manufacturers often need those costly collapsible cores which can really eat into budgets. Tooling expenses jump anywhere from 40 to 60 percent higher for things like valve bodies. The good news is 5 axis CNC machines handle undercuts pretty well through clever tool positioning angles. But watch out for those super thin walls under 0.8 mm in aluminum parts because they tend to bend or warp when tools deflect during machining. The Precision Machining Institute pointed this out back in 2022 after running some tests. Most shops stick to keeping wall thickness ratios below 5 to 1 across both casting and machining operations since going beyond that just invites trouble with stress buildup in the final product.

Production Volume, Cost-Effectiveness, and Lead Time Analysis

Cost Considerations in Metal Fabrication at Low vs. High Production Volumes

For small runs between 1 and 500 pieces, CNC machining really shines because there's not much needed in terms of special tools or complicated setups. What makes this work economically is that when making smaller quantities, those one-time costs for programming machines and creating fixtures get spread out over fewer items without dramatically increasing what each part costs. But look at the numbers from actual factory floor reports and something interesting happens around the 1,000 unit mark. Casting suddenly becomes about 40 to maybe even 60 percent cheaper than going with CNC methods. When companies start producing in high volumes, they can take advantage of cast molds and dies which were initially expensive but then get divided among thousands of products. This means individual parts end up costing roughly 85% less than if made through traditional CNC processes. The math just works better for large orders.

When Casting Becomes Economical: Production Volume Impact on Process Choice

When it comes to saving money on production runs, casting becomes more cost effective than CNC machining once we hit around 500 to 2000 units, though this really depends how complicated the part design actually is. For aluminum sand casting, most manufacturers find they break even financially somewhere around 800 pieces for medium sized components. Zinc alloy die casting tends to reach that same cost match point closer to 1200 units or so. Things get interesting with multi cavity molds too. These special setups can churn out 4 to 8 identical parts all at once, which means the sweet spot where casting beats machining happens much sooner than these numbers suggest. Many shops actually start seeing benefits from casting well before reaching those threshold counts when working with multiple cavities.

Break-Even Analysis: Units Where CNC Machining Services Lose Cost Advantage

For a standard 150mm aluminum housing, CNC machining costs $78/unit at 100 pieces. The same part in high-pressure die casting drops to $31/unit at 1,500 pieces—a 60% reduction. Tooling investments ($8k–$15k) for casting recoup within 18 months at 2,000+ unit annual production volumes. Below 300 units/year, CNC maintains a 22–35% cost advantage.

Turnaround Considerations for Urgent Orders Using CNC Machining Services

CNC delivers prototypes in 3–7 days versus 4–12 weeks for casting tooling development. For urgent 50-unit batches, CNC machining services provide 94% faster delivery than casting operations. This lead time advantage diminishes beyond 500 units, where casting’s per-day output (800–1,200 parts) surpasses CNC’s typical 50–100 parts/day capacity.

Strategic Decision-Making: Selecting Between CNC Machining and Casting

Hybrid Manufacturing: Combining Casting and CNC Machining for Optimal Results

Manufacturers today are turning more and more to hybrid manufacturing techniques that combine the best aspects of casting and CNC machining. The process starts with casting which cuts down on wasted materials since it creates parts that are already close to their final shape. Then comes the CNC work that gets those parts down to extremely tight tolerances around 0.005 mm according to ISO standards from last year. Take automotive turbine housings for instance many companies start with aluminum die casting to get the basic form right before switching over to CNC milling for those really important bearing areas where precision matters most. According to recent industry data from 2023, nearly seven out of ten manufacturers who mix these approaches report cutting their post processing time by about 40% without compromising on how accurate the final dimensions need to be.

Part Geometry Considerations for Manufacturing Efficiency and Cost

When dealing with complex internal channels or really thin walls below 1.5 mm thick, most engineers will go with CNC machining instead of casting because of those pesky draft angle requirements that casting needs. On the flip side, bigger items that are pretty uniform throughout, such as pump housings, often work out cheaper when made through sand casting methods. This is mainly because sand casting doesn't deal with all the complicated toolpaths that CNC machines require. For anyone designing parts, it's important to think about things like undercuts, how consistent the wall thicknesses need to be, and what kind of surface finish matters most right from the start. The surface finishes themselves differ quite a bit too - cast parts generally range between Ra 0.8 to 6.3 microns while machined parts can achieve smoother finishes from Ra 0.4 down to 3.2 microns depending on the process used.

Prototyping With CNC Machining vs. Casting: Speed, Iteration, and Validation

CNC machining can get functional prototypes out in just 2 to 5 days without needing any tooling money upfront, which really speeds up the design validation process. Casting prototypes tell a different story altogether. Traditionally they take anywhere from 3 to 6 whole weeks just to create patterns and set up molds. But there's good news these days thanks to 3D printed sand molds cutting that time down to around 7 to 10 days instead. When it comes to parts that need actual metallurgical tests, investment casting prototypes do give better material properties accuracy. The downside? They cost about three times what machined prototypes do. That's according to ASM International who published their findings back in 2023. So manufacturers have to weigh those material benefits against the budget hit when making production decisions.

Step-by-Step Decision-Making Framework for Selecting Between CNC and Casting

- Volume Analysis: Break-even points typically occur at 500–1,000 units, with casting becoming economical above this threshold

- Tolerance Requirements: Opt for CNC if ±0.025 mm or better precision is needed

- Material Constraints: High-temperature alloys like Inconel® require machining due to casting’s porosity risks

- Lead Time Needs: CNC services achieve 48-hour turnaround for urgent orders versus four or more weeks for permanent mold casting

This systematic approach reduces total production costs by 18–22% compared to single-process strategies, as reported in the Journal of Manufacturing Systems (2023).