Precision Engineering Unleashed: How CNC Machining Transforms High-Complexity Component Production

Multi-axis CNC | Precision tolerances | Aerospace & medical | Hybrid manufacturing

The Critical Role of CNC-Machined Components in Modern Industries

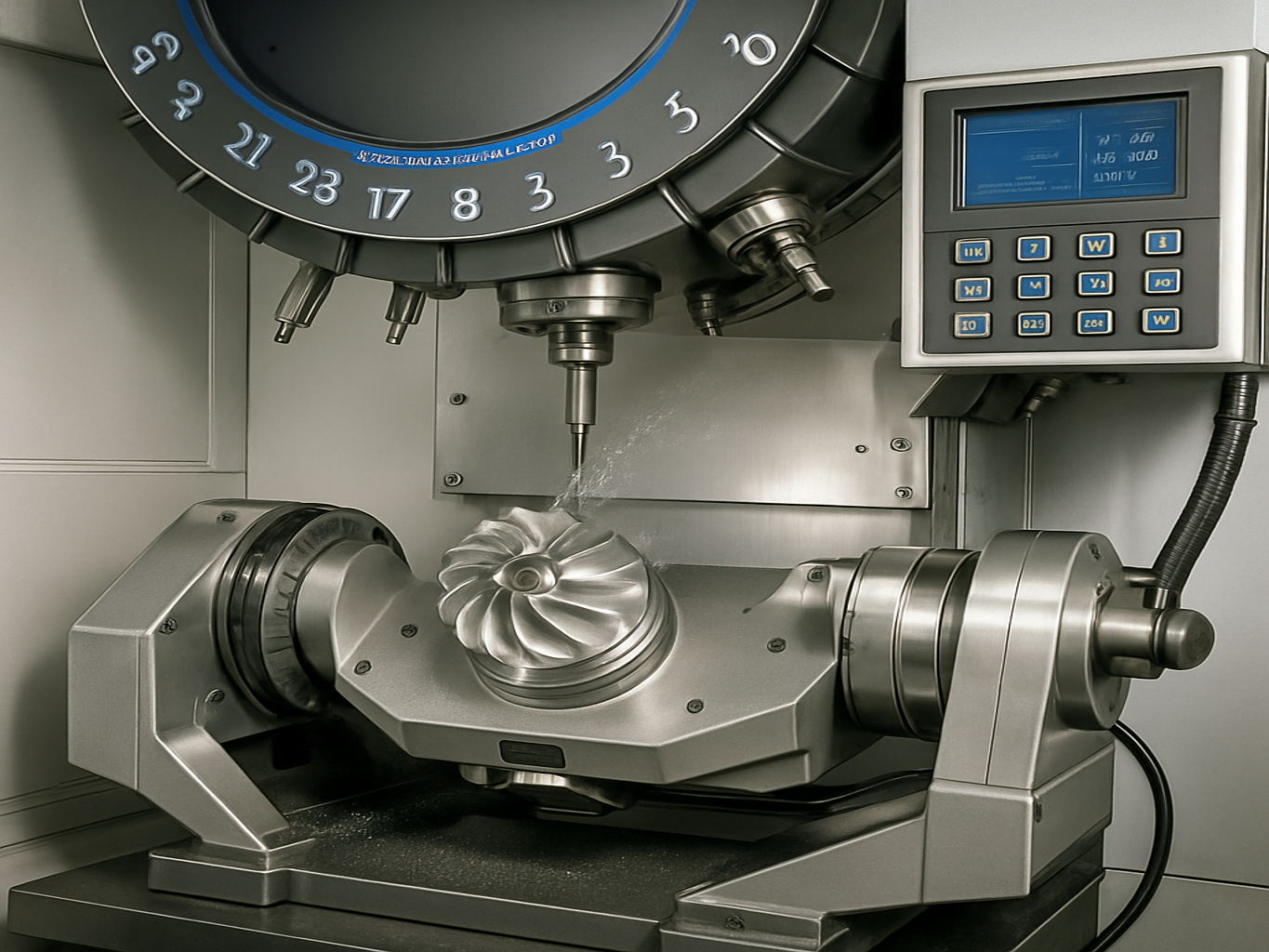

CNC machine parts have become indispensable in sectors demanding micron-level accuracy. For example, a Reddit user in r/Machinists noted, “Aerospace turbine blades require 5-axis CNC machining to achieve ±0.01 mm tolerances—manual methods simply can’t compete.” This aligns with industry trends where multi-axis systems reduce clamping errors by 40% (source: CNC Milling and Turning documentation).

Sino Rise Insight: Advanced CNC capabilities enable rapid iterations for prototypes, ensuring faster time-to-market for clients.

Overcoming Technical Hurdles in CNC Machining

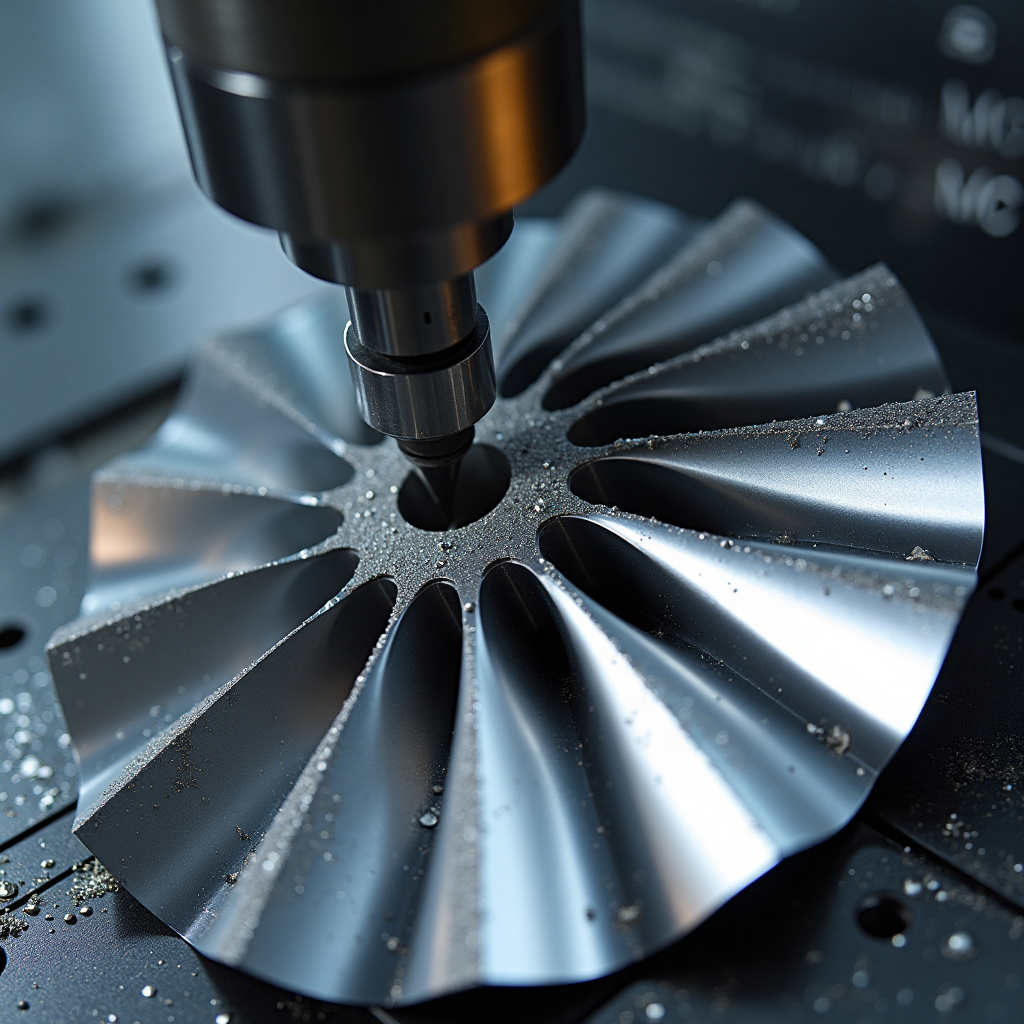

Challenge 1: Complex Geometry & Toolpath Optimization

Challenge 2: Material-Specific Machining

Machining Inconel 718? Reddit’s r/CNC community recommends PCBN tools with 70Bar coolant to combat work hardening. For aluminum alloys like 7075, mirror polishing (Ra ≤0.1µm) could extend part lifespan in medical devices (source: Integrated Surface Finishing Services).

Key Takeaway: Adaptive tooling and CAM software are non-negotiable for complex CNC machine parts.

Industry Applications Driving Demand for CNC-Machined Components

Aerospace: Turbine Blades & Lightweight Frames

As per a LinkedIn Aerospace Engineering report, titanium alloy components (e.g., Ti-6Al-4V) dominate 65% of aircraft engine parts, relying on 5-axis systems for contour accuracy.

Medical: Custom Implants & Micro-Tools

A Reddit r/MedicalDevices thread praised CNC-milled spinal implants for “perfect bone-contact surfaces,” achievable through micro-end mills (Ø0.1mm) and post-polishing.

Sino Rise Edge: Our fleet of 82 CNC machines supports multi-axis projects with integrated surface treatments like anodizing or electropolishing.

Future Trends in CNC Machining

Hybrid manufacturing (3D printing + CNC) is gaining traction. A case study on r/AdditiveManufacturing showed how laser-clad turbine blades reduced repair cycles by 30% post-CNC finishing. Additionally, AI-driven CAM tools could slash programming time by 40%, per IndustryWeek.